Black

The black version of the locking tube has been given an epoxy powder coating. This provides a degree of rust protection. If you need to use a locking tube in a wet or damp environment, however, we recommend that you use the stainless steel version.

Note: Locking tubes can only be used together with gas springs with threads.

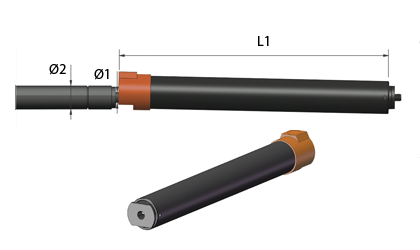

- LTN-6-80In stock: 109Material Black painted steelØ1 - fits rod size (mm) 0.2362Ø2 - Fits cylinder (mm) 0.5906L1 - Fits stroke length (mm) 3.1496

- LTN-6-100In stock: 36Material Black painted steelØ1 - fits rod size (mm) 0.2362Ø2 - Fits cylinder (mm) 0.5906L1 - Fits stroke length (mm) 3.9370

- LTN-6-150In stock: 87Material Black painted steelØ1 - fits rod size (mm) 0.2362Ø2 - Fits cylinder (mm) 0.5906L1 - Fits stroke length (mm) 5.9055

- LTN-6-200In stock: 77Material Black painted steelØ1 - fits rod size (mm) 0.2362Ø2 - Fits cylinder (mm) 0.5906L1 - Fits stroke length (mm) 7.8740

- LTN-8-100In stock: 85Material Black painted steelØ1 - fits rod size (mm) 0.3150Ø2 - Fits cylinder (mm) 0.7087L1 - Fits stroke length (mm) 3.9370

- LTN-8-150In stock: 267Material Black painted steelØ1 - fits rod size (mm) 0.3150Ø2 - Fits cylinder (mm) 0.7087L1 - Fits stroke length (mm) 5.9055

- LTN-8-200In stock: 306Material Black painted steelØ1 - fits rod size (mm) 0.3150Ø2 - Fits cylinder (mm) 0.7087L1 - Fits stroke length (mm) 7.8740

- LTN-8-250In stock: 284Material Black painted steelØ1 - fits rod size (mm) 0.3150Ø2 - Fits cylinder (mm) 0.7087L1 - Fits stroke length (mm) 9.8425

- LTN-10-100In stock: 248Material Black painted steelØ1 - fits rod size (mm) 0.3937Ø2 - Fits cylinder (mm) 0.9055L1 - Fits stroke length (mm) 3.9370

- LTN-10-150In stock: 211Material Black painted steelØ1 - fits rod size (mm) 0.3937Ø2 - Fits cylinder (mm) 0.9055L1 - Fits stroke length (mm) 5.9055

The black version is epoxy powder coated and thus resistant to corrosion.

The locking tube ensures that external elements such as wind, collisions, impacts, etc. do not cause a gate, for example, to close accidentally, risking injury to people or damage to property.

The function of the locking tube is easily neutralised with just one push.

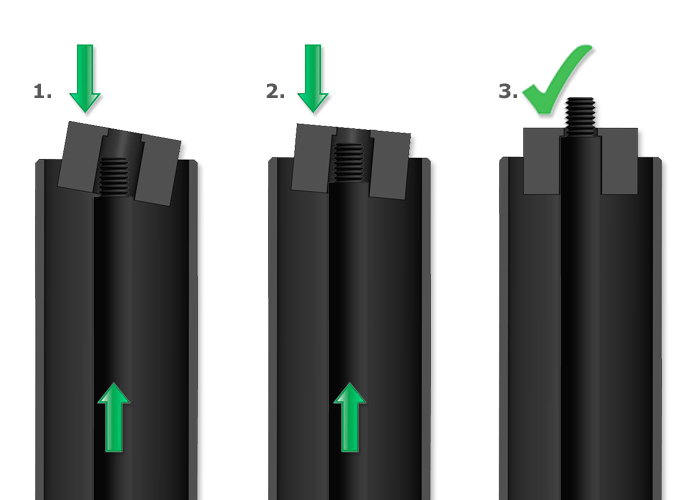

- When fitting the locking tube onto the gas spring it can be difficult to get the thread on the piston through the end piece of the locking tube. This is because of the spring-loaded end piece, which flips to the side to ensure correct spring function once.

- Press on the highest point of the end piece, and at the same time guide the piston through the hole in the end piece. Gas springs with a 6 mm piston are screwed into the end piece.

- The locking tube has now been fitted correctly, and the end fitting can be put on.