M-Struts - Mechanical "Gas Spring"

M-Struts for fast delivery!

Standard M-Struts are stock items and are available for fast delivery. Buy your M-Strut from our online shop now!

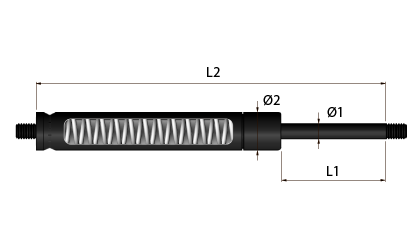

An M-Strut resembles a conventional compression gas spring. From its appearance, you cannot tell the difference, but inside the spring, the gas and gaskets have been replaced with an ordinary wire compression spring. M-Struts have the advantage of being a completely mechanical operation, so there is no risk of leaking gaskets, etc.

- LMS1505102In stock: 74Material Black painted steelØ1 - Piston Rod diameter (in) 0.2362Ø2 - Tube diameter (in) 0.5906L1 - Stroke (in) 2.0079L2 - Unloaded length between thread (in) 6.1417Fn - Maximum load at Ln (lbs) 6.0698G - Thread (in) 0.2362

- LMS1510205In stock: 63Material Black painted steelØ1 - Piston Rod diameter (in) 0.2362Ø2 - Tube diameter (in) 0.5906L1 - Stroke (in) 3.9764L2 - Unloaded length between thread (in) 12.1654Fn - Maximum load at Ln (lbs) 15.0622G - Thread (in) 0.2362

- LMS1515205In stock: 16Material Black painted steelØ1 - Piston Rod diameter (in) 0.2362Ø2 - Tube diameter (in) 0.5906L1 - Stroke (in) 5.9055L2 - Unloaded length between thread (in) 18.1496Fn - Maximum load at Ln (lbs) 15.0622G - Thread (in) 0.2362

- LMS1520306In stock: 98Material Black painted steelØ1 - Piston Rod diameter (in) 0.2362Ø2 - Tube diameter (in) 0.5906L1 - Stroke (in) 7.9921L2 - Unloaded length between thread (in) 24.1339Fn - Maximum load at Ln (lbs) 17.9847G - Thread (in) 0.2362

- LMS1525407In stock: 11Material Black painted steelØ1 - Piston Rod diameter (in) 0.2362Ø2 - Tube diameter (in) 0.5906L1 - Stroke (in) 10.0000L2 - Unloaded length between thread (in) 30.1575Fn - Maximum load at Ln (lbs) 20.9072G - Thread (in) 0.2362

- LMS1530507In stock: 67Material Black painted steelØ1 - Piston Rod diameter (in) 0.2362Ø2 - Tube diameter (in) 0.5906L1 - Stroke (in) 12.0079L2 - Unloaded length between thread (in) 36.1417Fn - Maximum load at Ln (lbs) 20.9072G - Thread (in) 0.2362

- LMS1805103In stock: 16Material Black painted steelØ1 - Piston Rod diameter (in) 0.3150Ø2 - Tube diameter (in) 0.7087L1 - Stroke (in) 2.0079L2 - Unloaded length between thread (in) 6.5354Fn - Maximum load at Ln (lbs) 8.9924G - Thread (in) 0.2362

- LMS1810207In stock: 40Material Black painted steelØ1 - Piston Rod diameter (in) 0.3150Ø2 - Tube diameter (in) 0.7087L1 - Stroke (in) 3.9370L2 - Unloaded length between thread (in) 12.5591Fn - Maximum load at Ln (lbs) 20.9072G - Thread (in) 0.2362

- LMS1815209In stock: 40Material Black painted steelØ1 - Piston Rod diameter (in) 0.3150Ø2 - Tube diameter (in) 0.7087L1 - Stroke (in) 5.9843L2 - Unloaded length between thread (in) 18.5433Fn - Maximum load at Ln (lbs) 26.9771G - Thread (in) 0.2362

- LMS1820309In stock: 42Material Black painted steelØ1 - Piston Rod diameter (in) 0.3150Ø2 - Tube diameter (in) 0.7087L1 - Stroke (in) 8.1102L2 - Unloaded length between thread (in) 24.5276Fn - Maximum load at Ln (lbs) 26.9771G - Thread (in) 0.2362

Piston = Steel, which is nitride-treated - resistant to corrosion.

Cylinder = Steel, painted black

Wire spring = Spring steel, Chrome Silicon Alloy

Working temperature between -40 ºC og +200 ºC

M-Struts - mechanical "gas spring" resembles a conventional compression gas spring. From its appearance, you cannot tell the difference, but inside the gas and gaskets have been replaced by an ordinary wire compression spring.

The wire spring gives M-Struts a regular linear force curve - in contrast to the flatter force curve of conventional gas springs. As M-Struts has no oil in the cylinder, it is not dampened in the last portion of its full extension.

M-Struts is used instead of gas springs in structures subject to impacts and vibrations. M-Struts may be used to great advantage in dirty and dusty environments, where a gas spring would suffer leakage due to its surroundings.

M-Struts is a good choice in structures where its function is used only rarely - such as emergency exits. M-Struts can cope with being subjected to loads over a prolonged period without being moved.

M-Struts must not be used as a stop, but should be incorporated so that it is controlled and limited by the movement of the structure.

The product is also useful for very heavy structures, where great forces are required. The standard range does not, however, cover this aspect. For this we can custom-design an M-Strut for the purpose. This will always be based on the particular problem.

Our large range of End Fittings can also be used on M-Struts - and provide great flexibility in installation.