Extension Springs - Galvanized Spring Steel

The C range is a small range of springs in electrogalvanised and stainless steel wire. The springs you see here, are galvanised. Although it is a small range, it is a good complement to Range A & B.

The electrogalvanised springs offer a small protection against corrosion, but not near as must as the stainless steel version. The dimensions are the same for electrogalvanised and stainless steel, the only difference being the force. The stainless steel springs are approximately 10% weaker than the galvanised ones.

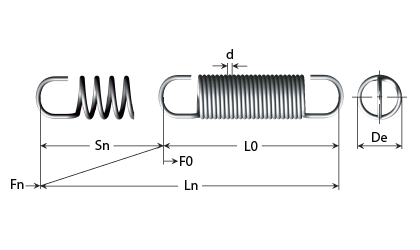

- 503In stock: 668Material Zinc Platedd - Wire diameter (in) 0.0236De - External diameter (in) 0.3150L0 - Unloaded length (in) 2.3228Ln - Max. loaded length (in) 11.5228Sn - Maximum travel (in) 9.2000Fn - Maximum load at Ln (lbs) 2.5066F0 - Initial force (lbs) 0.2248R - Spring constant (lb/in) 0.2855Range C

- 502In stock: 371Material Zinc Platedd - Wire diameter (in) 0.0315De - External diameter (in) 0.3543L0 - Unloaded length (in) 1.5354Ln - Max. loaded length (in) 5.2681Sn - Maximum travel (in) 3.7327Fn - Maximum load at Ln (lbs) 5.0335F0 - Initial force (lbs) 0.6744R - Spring constant (lb/in) 1.1991Range C

- 501In stock: 1,328Material Zinc Platedd - Wire diameter (in) 0.0335De - External diameter (in) 0.2756L0 - Unloaded length (in) 1.3583Ln - Max. loaded length (in) 2.6925Sn - Maximum travel (in) 1.3343Fn - Maximum load at Ln (lbs) 7.5693F0 - Initial force (lbs) 1.3489R - Spring constant (lb/in) 4.6823Range C

- 504In stock: 2,786Material Zinc Platedd - Wire diameter (in) 0.0335De - External diameter (in) 0.3150L0 - Unloaded length (in) 2.3622Ln - Max. loaded length (in) 6.2386Sn - Maximum travel (in) 3.8764Fn - Maximum load at Ln (lbs) 6.6768F0 - Initial force (lbs) 1.1240R - Spring constant (lb/in) 1.4275Range C

- 505In stock: 1,989Material Zinc Platedd - Wire diameter (in) 0.0394De - External diameter (in) 0.3543L0 - Unloaded length (in) 2.3819Ln - Max. loaded length (in) 5.7587Sn - Maximum travel (in) 3.3768Fn - Maximum load at Ln (lbs) 9.4038F0 - Initial force (lbs) 1.5737R - Spring constant (lb/in) 2.3412Range C

- 507In stock: 5,681Material Zinc Platedd - Wire diameter (in) 0.0394De - External diameter (in) 0.3937L0 - Unloaded length (in) 4.4094Ln - Max. loaded length (in) 13.2937Sn - Maximum travel (in) 8.8843Fn - Maximum load at Ln (lbs) 8.5090F0 - Initial force (lbs) 1.3489R - Spring constant (lb/in) 0.7994Range C

- 508In stock: 914Material Zinc Platedd - Wire diameter (in) 0.0492De - External diameter (in) 0.5118L0 - Unloaded length (in) 2.5000Ln - Max. loaded length (in) 7.2083Sn - Maximum travel (in) 4.7083Fn - Maximum load at Ln (lbs) 12.3667F0 - Initial force (lbs) 1.7985R - Spring constant (lb/in) 2.2270Range C

- 506In stock: 15Material Zinc Platedd - Wire diameter (in) 0.0551De - External diameter (in) 0.4331L0 - Unloaded length (in) 3.2677Ln - Max. loaded length (in) 6.8909Sn - Maximum travel (in) 3.6232Fn - Maximum load at Ln (lbs) 19.8371F0 - Initial force (lbs) 1.3489R - Spring constant (lb/in) 5.0820Range C

- 510In stock: 1,522Material Zinc Platedd - Wire diameter (in) 0.0591De - External diameter (in) 0.6299L0 - Unloaded length (in) 5.1575Ln - Max. loaded length (in) 16.0791Sn - Maximum travel (in) 10.9217Fn - Maximum load at Ln (lbs) 16.8764F0 - Initial force (lbs) 2.4729R - Spring constant (lb/in) 1.3133Range C

- 509In stock: 616Material Zinc Platedd - Wire diameter (in) 0.0689De - External diameter (in) 0.5512L0 - Unloaded length (in) 4.9213Ln - Max. loaded length (in) 9.9705Sn - Maximum travel (in) 5.0492Fn - Maximum load at Ln (lbs) 29.3735F0 - Initial force (lbs) 5.3954R - Spring constant (lb/in) 4.7394Range C

DIN 17223 C-Wire WERKSTOFF NO. 1.200

Working temperature between -30 ºC and +120 ºC

The galvanised range is manufactured of electro-galvanised music wire. Electro-galvanisation means that the spring gets a blank and more corrosion resistant surface.

Fn for stainless steel spring steel is approx. 0.88 x Fn for music wire.

Calculation of the initial force (F0):

The initial force F0 or the initial tension is for guidance only due to differing production processes.

F0 = Fn - (R * Sn). A rule of thumb is however that F0 is 10-15% of Fn.

For example, for stock number 32600, Fn = 237 N, R = 2,67N/mm og Sn = 75,70mm. F0 = 237N - (2,67N/mm * 75,70mm) = 237N - 202N = 35N

The calculation of spring force for a given length:

Calculation of spring force at a given length is: F0 + (travel * R).

For example, for stock number 32600 where R = 2.67 N/mm, the desired travel is 55 mm and F0 is approx. 35 N. 35N + (55mm * 2,67N/mm) = 35N + 147N = 182N

Normally right-handed

Standard springs are not defined with a specific direction of wind. Depending on production, the springs may be produced either right or left wound. If you require a specific direction of wind a special spring must be produced.

If an extension spring with an exact value for one of the following parameters is required, springs must be custom-made:

- Loop type

- Loop height (LH)

- Loop position (X)

- Loop width (if the spring is to be incorporated into a tube)

- Opening at loop (m)

- Initial force (F0)