Compression Springs - Stainless Steel

8-70015-description

Stainless steel 302

8-70024-description

Stainless steel 316

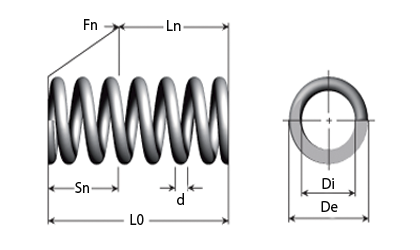

- C00570060120SIn stock: 659Material Stainless steel 302d - Wire diameter (in) 0.0059De - External diameter (in) 0.0571Di - Internal diameter (in) 0.0453L0 - Unloaded length (in) 0.1201Ln - Max. loaded length (in) 0.0610Sn - Maximum travel (in) 0.0591Fn - Maximum load at Ln (lbs) 0.1911R - Spring constant (lb/in) 3.1406Range B

- C00570060190SIn stock: 1,509Material Stainless steel 302d - Wire diameter (in) 0.0059De - External diameter (in) 0.0571Di - Internal diameter (in) 0.0453L0 - Unloaded length (in) 0.1902Ln - Max. loaded length (in) 0.0902Sn - Maximum travel (in) 0.1000Fn - Maximum load at Ln (lbs) 0.1911R - Spring constant (lb/in) 1.8272Range B

- C00570060250SIn stock: 640Material Stainless steel 302d - Wire diameter (in) 0.0059De - External diameter (in) 0.0571Di - Internal diameter (in) 0.0453L0 - Unloaded length (in) 0.2500Ln - Max. loaded length (in) 0.1142Sn - Maximum travel (in) 0.1358Fn - Maximum load at Ln (lbs) 0.1911R - Spring constant (lb/in) 1.3133Range B

- C00570060310SIn stock: 8,649Material Stainless steel 302d - Wire diameter (in) 0.0059De - External diameter (in) 0.0571Di - Internal diameter (in) 0.0453L0 - Unloaded length (in) 0.3098Ln - Max. loaded length (in) 0.1382Sn - Maximum travel (in) 0.1717Fn - Maximum load at Ln (lbs) 0.1911R - Spring constant (lb/in) 1.0849Range B

- C00570060380SIn stock: 1,780Material Stainless steel 302d - Wire diameter (in) 0.0059De - External diameter (in) 0.0571Di - Internal diameter (in) 0.0453L0 - Unloaded length (in) 0.3799Ln - Max. loaded length (in) 0.1669Sn - Maximum travel (in) 0.2130Fn - Maximum load at Ln (lbs) 0.1911R - Spring constant (lb/in) 0.9136Range B

- C00570060440SIn stock: 532Material Stainless steel 302d - Wire diameter (in) 0.0059De - External diameter (in) 0.0571Di - Internal diameter (in) 0.0453L0 - Unloaded length (in) 0.4402Ln - Max. loaded length (in) 0.1929Sn - Maximum travel (in) 0.2472Fn - Maximum load at Ln (lbs) 0.1911R - Spring constant (lb/in) 0.7423Range B

- C00570060500SIn stock: 311Material Stainless steel 302d - Wire diameter (in) 0.0059De - External diameter (in) 0.0571Di - Internal diameter (in) 0.0453L0 - Unloaded length (in) 0.5000Ln - Max. loaded length (in) 0.2181Sn - Maximum travel (in) 0.2819Fn - Maximum load at Ln (lbs) 0.1911R - Spring constant (lb/in) 0.6852Range B

- C00570060560SIn stock: 189Material Stainless steel 302d - Wire diameter (in) 0.0059De - External diameter (in) 0.0571Di - Internal diameter (in) 0.0453L0 - Unloaded length (in) 0.5598Ln - Max. loaded length (in) 0.2591Sn - Maximum travel (in) 0.3008Fn - Maximum load at Ln (lbs) 0.1911R - Spring constant (lb/in) 0.6852Range B

- C00570060620SIn stock: 180Material Stainless steel 302d - Wire diameter (in) 0.0059De - External diameter (in) 0.0571Di - Internal diameter (in) 0.0453L0 - Unloaded length (in) 0.6201Ln - Max. loaded length (in) 0.2858Sn - Maximum travel (in) 0.3343Fn - Maximum load at Ln (lbs) 0.1911R - Spring constant (lb/in) 0.5710Range B

- C00570070120SIn stock: 37Material Stainless steel 302d - Wire diameter (in) 0.0071De - External diameter (in) 0.0571Di - Internal diameter (in) 0.0429L0 - Unloaded length (in) 0.1201Ln - Max. loaded length (in) 0.0669Sn - Maximum travel (in) 0.0531Fn - Maximum load at Ln (lbs) 0.3170R - Spring constant (lb/in) 5.8244Range B

DIN 17224 AISI 302 WERKSTOFF NO. 1.4310

Working temperature between -200 ºC and +250 ºC

Produced in stainless steel for use in all environments.

Range A: (The A Range consists of springs with 5 digits, ie: "12200")

IN 2098 defines the spring's dimensions based on wire thickness. Contact Sodemann-Springs.US for further information.

DIN 2095 defines the force as the determining parameter. The number of coils may therefore vary. L0 is for guidance only and may well be longer than stated in the tables. Deviations are usually observed in a large coil ratio (Dm/d), where the spring has a thin wire in relation to the diameter. Once loaded the spring will set itself and thus achieve the correct force at the correct travel. Contact Sodemann-Springs.US for further information.

Range B: (The B Range consists of springs with 11 digits and 2 letters, ie: "C07200853000M")

On this range, the number of coils is not shown, because the spring is produced after the force as the primary measurement. Therefore the variation in wire size, through tolerance or availability, will always have an effect on the number of coils.

Fn for stainless steel spring steel is approx. 0.88 x Fn for music wire.

Calculation of spring force at a given length is travel s * R

For example:

A spring is compressed 16 mm and the spring constant is 3 N (16 mm * 3 N = 48 N)

A spring that travels 16 mm thus produces 48 N, which equates to approx. 4.8 kg.

If compression springs with a very high spring constant/carrying capacity are required, coloured die springs are recommended.

Range A: Wire up to and including 0.8 mm is closed, but unground. Wire from 1.0 mm is closed and ground.

Range B: Outside diameter up to and including 2,24 mm is closed, but unground. Outside diameter from 3,05 mm is closed and ground

Normally right-handed

If the springs are compressed to Ln, the spring will set itself. It will then not return to its original length, L0.

Always dimension a spring so that it delivers the desired travel and force with as little exertion as possible. This prolongs the service life of the spring. Applying maximum load to the spring will shorten its service life and cause it to become permanently distorted.