How do you design an extension spring?

We design extension springs every single day, so we come across the same questions again and again.

Here we will go through the construction of an extension spring, and explain the sequence of events.

Extension spring material

First choose the material that matches your purpose and design. For correct calculation of your extension spring, the material is the starting point.

Extension spring diameter

An extension spring rarely has any internal space considerations - it is therefore natural to take an extension spring's outside diameter as a starting point for the spring calculation.

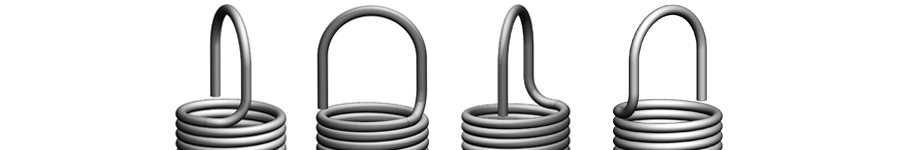

Extension spring loops

Standard extension springs are basically supplied with German loops (high German loop shown below)

The loop is the weak part of the extension spring, and this is where we most often see damage.

Always avoid lateral cracks to the loop, and make sure the spring does not twist as it moves. Any load the loop is subjected to - over and above the intended straight pull - will limit its service life.

When the spring is mounted, care should also be taken to ensure it is mounted correctly without any load on the loop.

If you want to use the extension spring in special assemblies, it is recommended that you make a special extension spring with ends that match your needs - perhaps a coned end with a bolt, a loose loop or a screwed-in eye plate as mounting options.